Corrosion Risk Profiling

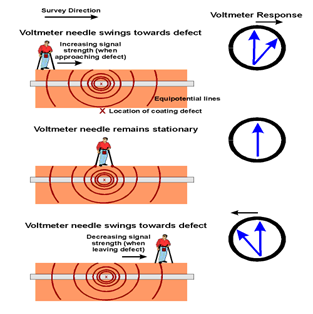

Corrosion risk profiling with the aid of non-invasive DCVG coating defect survey techniques. Know exactly where to dig when you dig. We use non-intrusive DC measurement techniques to detect coating defects on your buried pipeline.

Overall Condition Assessment through Pipeline Corrosion Risk Profiling

Pipe and Tank Africa uses advanced technologies and techniques that allow for early and precise detection of sites of past or present corrosion. With this information you, the pipeline owner, can adopt a proactive approach and apply immediate mitigation measures to prevent further deterioration. The extent of the current damage can also be quantified so that we can determine the necessary requirements to refurbish your pipeline.

What we do:

The biggest contributor to the deterioration of buried steel pipelines is external corrosion. In many cases, the decline of a pipeline only becomes apparent when the first leaks or failures occur. By this time the damage is normally quite widespread and expensive, major refurbishment is required to ensure safe and reliable operation.

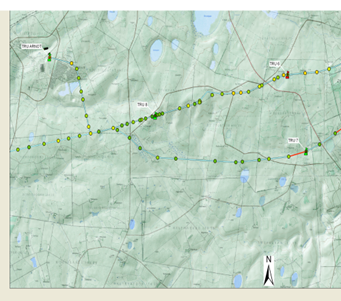

A topographic map and GIS representation of condition assessment data collected by Pipe and Tank Africa

External corrosion will occur at all sites where the coating has been compromised. Pipe and Tank Africa utilises sophisticated non-intrusive DC measurement techniques to detect coating defects. We then evaluate the electrochemical, microbial and electrolytic parameters at each site and grade each coating defect in terms of present and past corrosion risk. Our grading system is then calibrated by physical inspection.

A detailed report of the entire pipeline’s corrosion risk profile is compiled. The report includes geo-referenced data in a user-friendly visual format, the mitigation measures required to prevent further deterioration, and indications of risk areas where targeted NDT should be carried out. This is an excellent alternative in situations where deterioration assessments by means of extensive internal NDT methods are not practically or commercially viable.